Chalmers University has announced details of a project in collaboration with Siemens Digital Industries Software.

Determining a ship's resistance at full scale is crucial for designing energy-efficient vessels. Computational fluid dynamics offer an exciting alternative to traditional methods, but full-scale resistance measurements are needed for validation – and have now become available in an unlikely way.

The Lucy Ashton carried passengers on the river Clyde between 1888 and 1949, one of the longest-serving Clyde steamers. (Image provided by the Scottish Maritime Museum)

The paddle steamer Lucy Ashton operated as a passenger vessel in Scotland between 1888 and 1949. During the 1950's, she was used in a spectacular research experiment in ship resistance – an area that is to this day one of the most challenging in ship design. In the year 2020 Dr Dmitriy Ponkratov, Marine Director at Siemens Digital Industries Software and a founder of the JoRes Joint Research project, downloaded some old journal articles to entertain himself during a flight. Little did he know that he would find a missing part to unlock new opportunities for future digitalisation of the maritime industry.

The challenges of full-scale resistance predictionShip resistance prediction at full scale traditionally relies on the International Towing Tank Conference (ITTC) recommended procedure, which has its roots in towing tank model scale tests. Despite being today's best practice and a widely used procedure, it is based on several old assumptions that can introduce uncertainties in full-scale resistance prediction. In the future, the aim is to use Computational Fluid Dynamics (CFD) instead.

“Recent advancements in CFD offer a promising alternative to the ITTC procedure by enabling direct full-scale ship resistance prediction. This approach may not only significantly improve the accuracy and reliability of ship resistance predictions but can also provide more information about the flow details around a full-scale ship.

However, before fully adopting CFD for full-scale resistance predictions, it must be validated through comparison with full-scale resistance measurements, which are rare” says Arash Eslamdoost, associate professor in applied hydrodynamics at the Department of Mechanics and Maritime Sciences. Recent JoRes project tests on seagoing vessels aimed to develop real-scale CFD validation cases. These tests, however, couldn’t separate hull and propeller forces.

"Ideally, vessel resistance should be measured without the propeller to understand undisturbed hull flow. Towing by another vessel is a straightforward solution, but it introduces wake interference. The alternative of using two tugboats also disrupts the wave pattern, affecting resistance measurements. As far as full-scale resistance measurements go, it seems to me very difficult to find a better setup than the Lucy Ashton's one-of-a-kind campaign" says Rui Lopes, postdoc at the Department of Mechanics and Maritime Sciences.

Spectacular 1950's experiment

The same problems are likely to have bothered the engineers at British Ship Research Association (BSRA) around 1950, when they came up with the elegant solution to call the Rolls Royce company and check whether they could get four jet engines from aeroplanes to install on a vessel. The answer was positive, and BSRA acquired the old paddle steamer Lucy Ashton, built in 1888, and transformed her into the first and only research vessel equipped with jet engines. The wheelhouse was soundproofed by BBC, and hand brakes were installed for safety – two flaps could literally be submerged in the water to slow down the vessel.

These great experiments significantly contributed to maritime science and were recognised by the ITTC at that time. But when digital technologies and Computational Fluid Dynamics started to develop in the 1990’s, they seem to have been forgotten.“When I learned about the details of the case, it was clear it formed a unique opportunity to validate full-scale resistance predictions made by CFD” says Rickard Bensow, professor at the Department of Mechanics and Maritime Sciences. To make use of the rediscovered data the Division of Marine Technology at the Department of Mechanics and Maritime Sciences launched a global workshop to calculate and validate various CFD codes by comparing the results of the calculations with actual measurements performed in the 1950's.

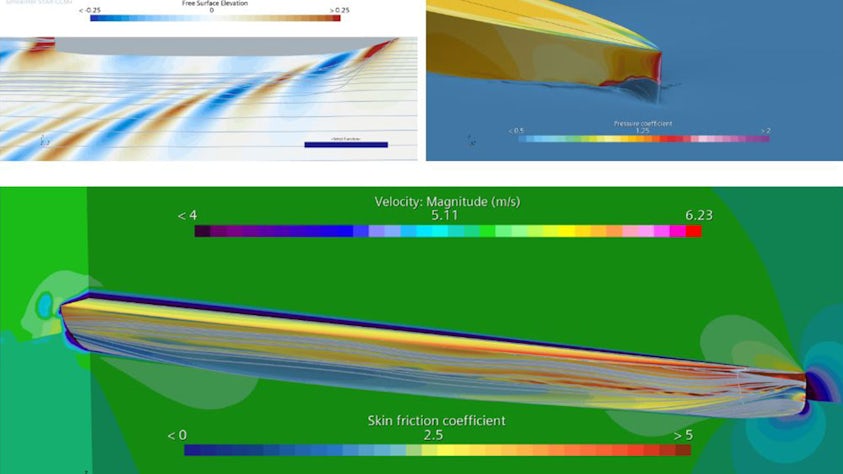

CFD simulations of Lucy Ashton made with Simcenter STAR-CCM+

At the announcement of the workshop 79 companies showed interest, of which 46 companies from 20 countries ended up submitting their results, making it the largest workshop in the maritime community. All of the contributing companies have been invited to a one-day in-person meeting at Chalmers on September 25.

"We hope that this meeting will serve as an important step in encouraging further discussion and knowledge-sharing of the results for the benefit of future energy-efficient vessels", says Rickard Bensow.

Read more at the Chalmers University newsroom or the Simcenter blog.